TRONOMER-Thermoplastic-elastomers TPE

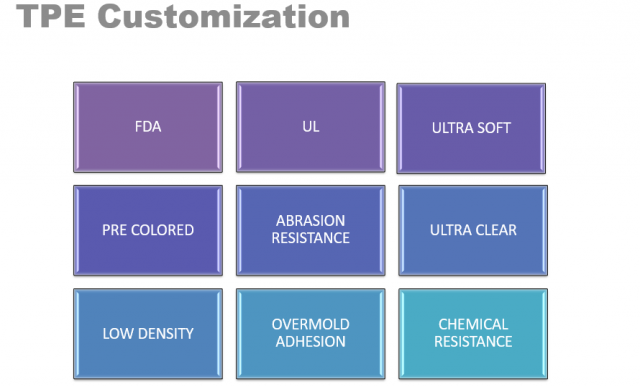

If your application requires something even more special, our experts will work with you to develop unique formulations to help you create products that will dazzle your customers.

![]() compounds are high performance Thermoplastic Elastomers, with their broad range of base chemistries. Designed specifically for the production molded and extruded products.

compounds are high performance Thermoplastic Elastomers, with their broad range of base chemistries. Designed specifically for the production molded and extruded products.

![]() TPEs are designed to improve ergonomics, enhanced grip performance, improved aesthetics, and critical impact protection. Also, to meet the requirements and end-use environments in the range from consumer goods to medical instruments, building and construction, transportation and industrial markets. This family of thermoplastic elastomers utilizes multiple technologies to create formulations with drilled-down, specialized characteristics.

TPEs are designed to improve ergonomics, enhanced grip performance, improved aesthetics, and critical impact protection. Also, to meet the requirements and end-use environments in the range from consumer goods to medical instruments, building and construction, transportation and industrial markets. This family of thermoplastic elastomers utilizes multiple technologies to create formulations with drilled-down, specialized characteristics.

Highlights

- Excellent weather resistance

- FDA

- Transparent

- Soft (Shore A 10-100)

- Excellent elongation

- Extrusion, injection, and blow moldable

- Wide service temperature (-60°C ~ 120°C)

- High tensile strength, tear strength

- Excellent physical properties

| TRONOMER NB Series | Bonding for ABS,PC, PC/ABS | Excellent weather resistance | UL Compliance |

| TRONOMER NA Series | Bonding for PA (Nylon) | Good adhesion for double injection | UL Compliance |

| TRONOMER M Series | Good elasticity | Apply for medical instruments | FDA Compliance |

| TRONOMER NE Series | Bonding for PP | Excellent weather resistance | UL Compliance |

| TRONOMER ND Series | Bonding for PS, HIPS | Good adhesion | Good printing properties |

| TRONOMER NN Series | Normal grade | Competitive edge in cost | Good aesthetics |

| TRONOMER N3 Series | EPDM base | Good to replace detonative rubber | For injection and compression |

| TRONOMER N4 Series | TPCC base | Good for automotive, industrial, wire & cable | For extrusion and injection |

Thermoplastic Elastomers Silicone

Better alternative to silicone. Combination of strength, toughness, and abrasion resistance of a thermoplastic elastomer with the soft silkiness, UV and chemical resistance, and colorable of silicone.

Highlights

- Non-tacky, dirt resistance

- Aesthetics

- Silky touch

- Easy to process and resistant to color degradation

- Better tear resistance

- Weather and environmental resistance